LETTERING SYSTEM

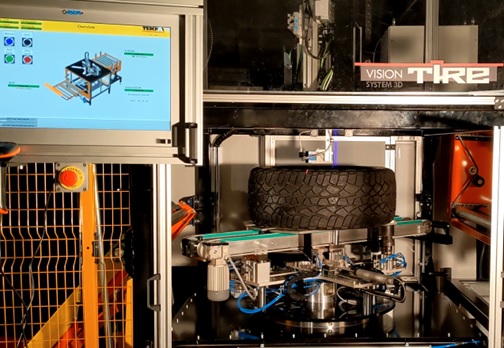

Vision Tire System 3D – Lettering System can read and verify automatically every kind of writing and symbols on the outside of a not inflated tire with an high efficiency and high repetibility process, replacing the manual inspection that is an high focus and high risk procedure.

What it Does

STAMP READING

SYMBOLS CONTROL

MISPLACEMENT DETECTION

DIRTY STAMP DETECTION & MORE

VISION TIRE SYSTEM 3D – LETTERING

Utilizing Laser Profilometry, a technique based on triangulation between a laser line and an area scan camera, the system achieves a highly detailed three-dimensional reconstruction of the tire surface with one of the highest possible resolutions in an extremely short cycle time.

Specifically designed for first cured tire inspection, the system ensures that all required writings and symbols are correctly imprinted and positioned on the tire surface, based on the plant sheet specifications. It also enables additional quality checks, such as monitoring mold wear by comparing the actual stamp height of the characters to the expected values. A tolerance threshold can be set to trigger alerts when the mold becomes dirty, deteriorated, or damaged, ensuring consistent marking quality and preventing defects early in the production process.

VISION TIRE SYSTEM 3D – LETTERING

In tire production, a critical phase is the lettering procedure, especially during the first cured tire inspection. This step ensures that all required writings and symbols are correctly imprinted and positioned on the tire surface. Compliance with international regulations, which mandate specific markings, and the overall perceived quality of the tire make lettering control a crucial process in production.

Vision Tire System 3D – Lettering is specifically designed for first cured tire inspection, automatically reading and verifying all writings and symbols on the exterior of a non-inflated tire. With high efficiency and repeatability, it replaces manual inspection—a task that requires intense focus and carries a high risk of errors—ensuring greater accuracy and consistency in quality control.