VISION TIRE SYSTEM 3D

DEFECT DETECTION

An innovative three-dimensional vision system to reconstruct a 3D model of the tire in test and operates specialized algorithms for every different issue on the tire. – Patented in Europe, Asia and America.

What it Does

complete tire inspection

Defect detection

defect classification

defect measurement

VISION TIRE SYSTEM 3D – DEFECT DETECTION

In the tire production process, one of the most sensitive stages is the control operated on every single item that no defects have occurred during the production process, before it will be sent on the market.

Technologies have integrated methodologies and advanced tools to achieve more efficient and reliable controls, but there are still some parts of this process that are conducted manually by specialized workers. Automate these operations would give a great competitive advantage, considering the impact of the cost of qualified workforce and the need of objectivity in all the control phases.

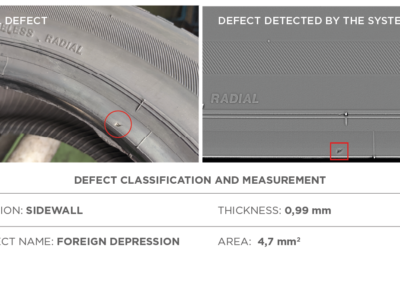

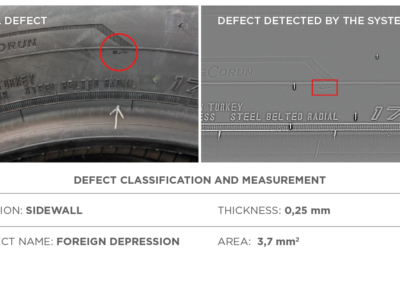

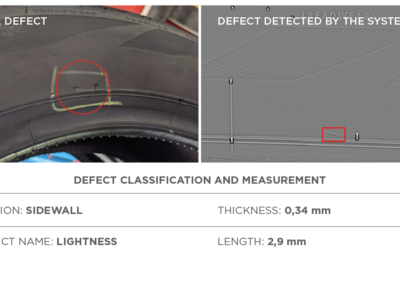

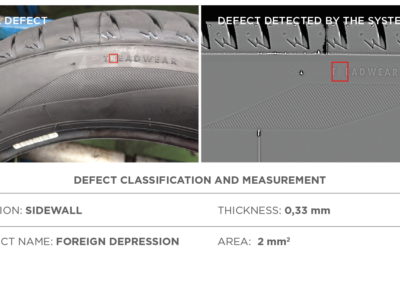

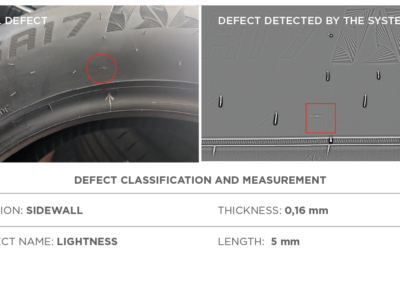

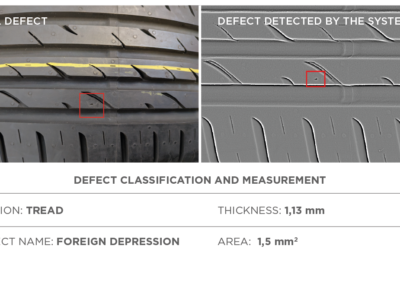

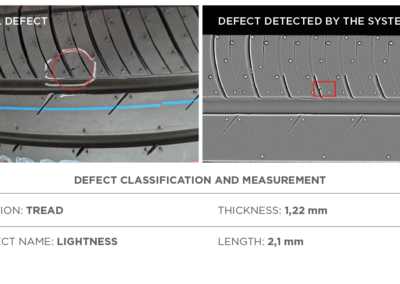

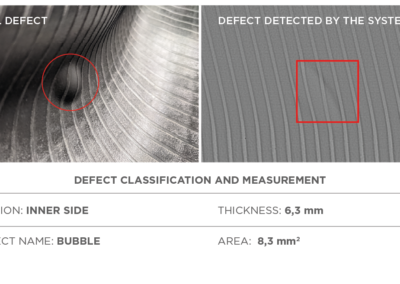

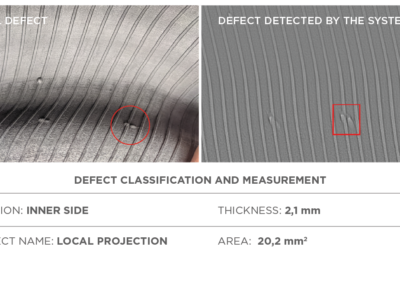

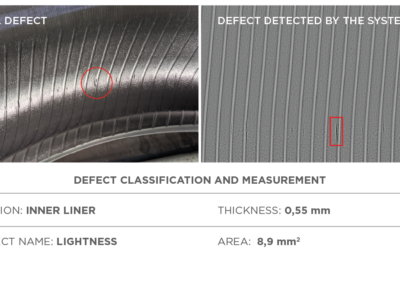

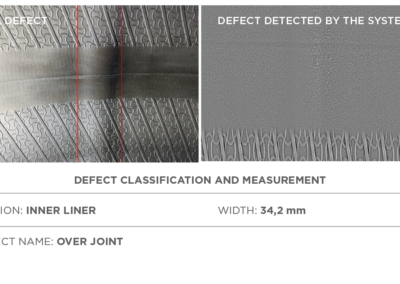

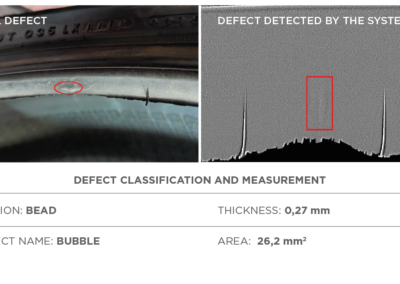

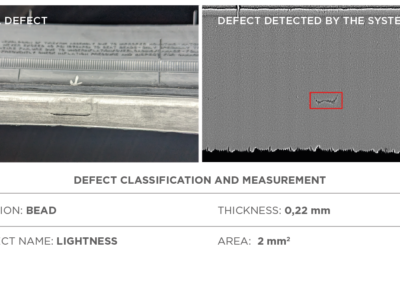

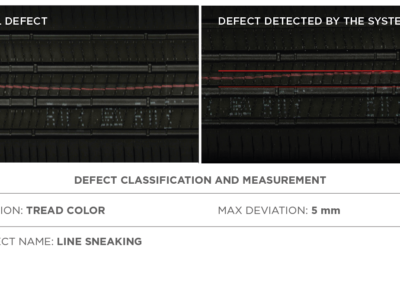

Vision Tire System 3D is an innovative three-dimensional vision system to detect any defect that occurred on the tire. Reconstructing a 3D model of the tire in all its areas and operating specialized algorithms for every different sector, Vision Tire System 3D can detect and classify automatically every kind of defect that can be occured on the tire during the production process (bubble, scratch, bladder, cut, scuffing, foreign body etc), with an high efficiency and a remarkable saving in terms of time and costs.

VISION TIRE SYSTEM 3D

DEFECT DETECTION

VISION TIRE SYSTEM 3D uses the LASER PROFILOMETRY, a technique based on the triangulation between a laser and a camera that let the system have a three-dimensional reconstruction of the whole tire with one of the highest possible resolution in a very short cycle time.

The system is equipped with six laser-camera tools that allow it to inspect all areas of the tire. These vision units are mounted on precision axes that operate according to preset parameters, depending on the tire to be inspected.

This setup ensures that every millimeter of the tire, both inside and outside, is thoroughly scanned.

The control software processes all acquired data, detecting any defects that may have occurred during the production process and delivering results in near real-time.