Vision Systems for Tire Production Lines

ADDITIONAL CHECK

Leverage advanced machine vision solutions for real-time monitoring and inspection. Ensure every tire meets the highest quality standards by detecting defects early in the production process. Reduce waste and improve overall efficiency with our tailored solutions.

What it Does

Defect Detection

Dimension Inspection

Process Monitoring

Quality Assurance

Vision System

The industrial vision system includes all applications that use cameras, intelligent sensors and software algorithms to capture real images and process them in order to provide the production line with information needed for automation or quality control. The system ensures the highest production efficiency and quality by being able to make 100% objective and repetitive visual inspection with no error margin.

Tekna Automazione e Controllo can design, install and program vision systems suitable for different customer requirements, identifying the best solution between 2D, 3D, monochrome or color vision. 1D and 2D readers, matrix cameras, linear cameras, profilometers and more are the most popular options on the market for developing vision machine applications.

Years Established

Completed Projects

ADDITIONAL CHECK

Tire Dot Code Reading Application

An innovative application designed for the on-the-fly reading of tire DOT codes directly on production lines. By leveraging advanced laser profilometry, the system ensures consistent and reliable code reading, regardless of environmental conditions such as lighting variations or surface reflectivity.

The system integrates seamlessly with the customer’s MES (Manufacturing Execution System), receiving the expected code information in real time. It verifies that the DOT code is correctly printed on the tire, ensuring full compliance with production requirements.

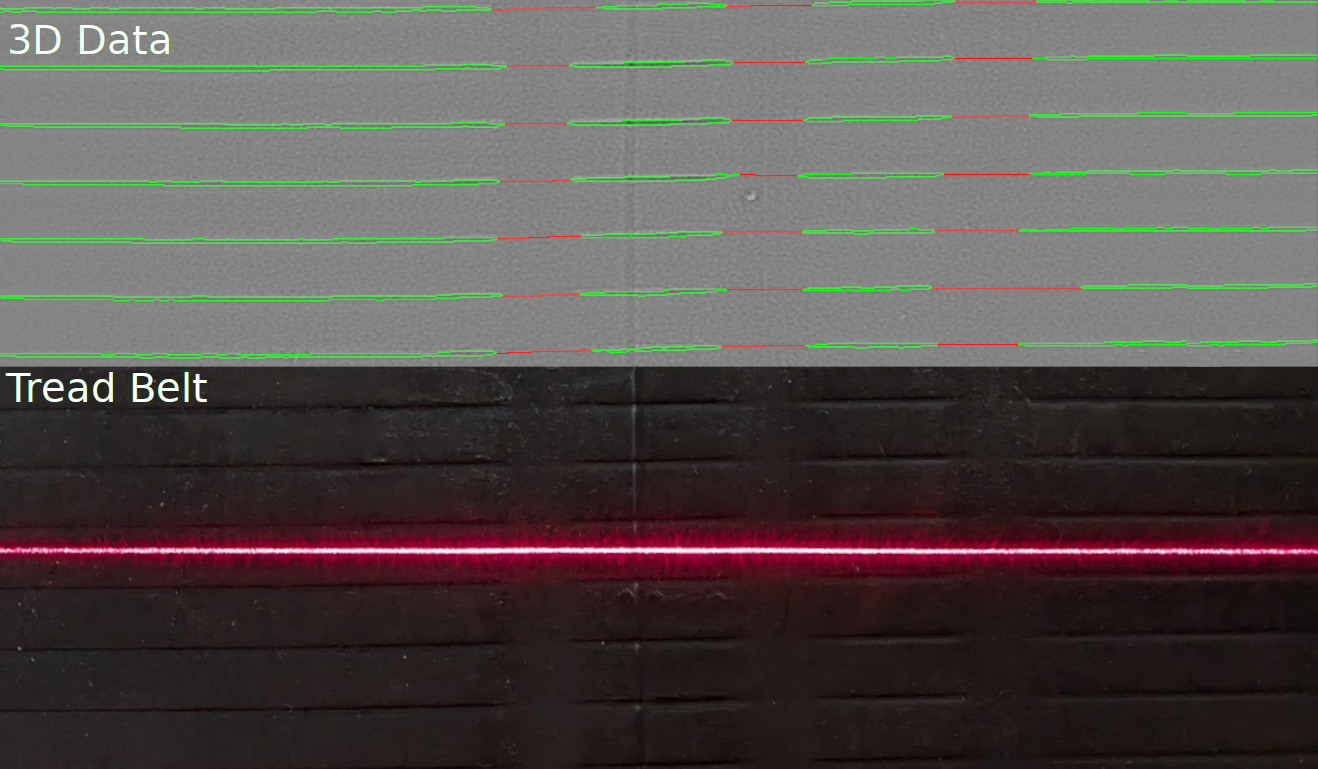

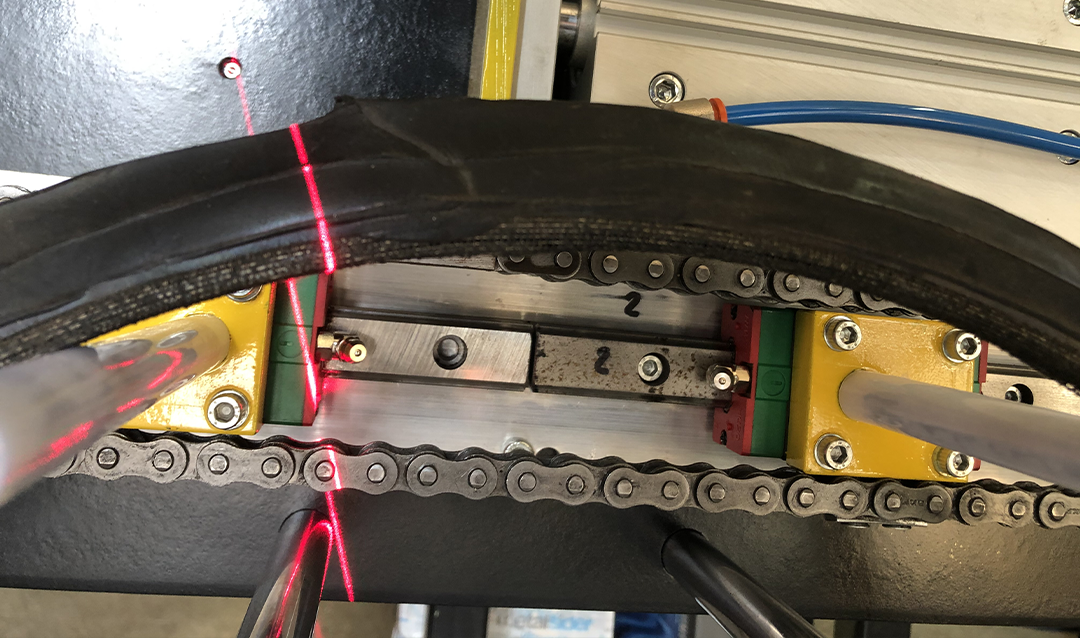

On-the-Fly Inspection of Extruded Treads

This application ensures in-line quality control of freshly extruded treads with embossed grooves along their entire length. The system verifies that all grooves are properly formed, uninterrupted, and meet specified depth and spacing requirements. Providing precise real-time feedback, it guarantees high-quality production standards while reducing waste and manual inspections.

Tread Profile Inspection Application

This offline inspection application is designed to ensure that the tread profile of a finished tire section complies with the specified design. With an accuracy of up to one-tenth of a millimeter, the system guarantees that the tread profile evolution precisely matches the original specifications. By providing detailed and reliable measurements, the application helps maintain the highest standards of quality and adherence to design requirements.

Red and Yellow Dot Quality Inspection Application

This in-line quality control application uses a color camera to verify the presence, color, and size of red and yellow dots on tires. The system ensures that each dot meets the specified standards for proper identification and alignment. By performing precise, real-time inspections, it guarantees compliance with production requirements and eliminates defects related to marking inconsistencies.

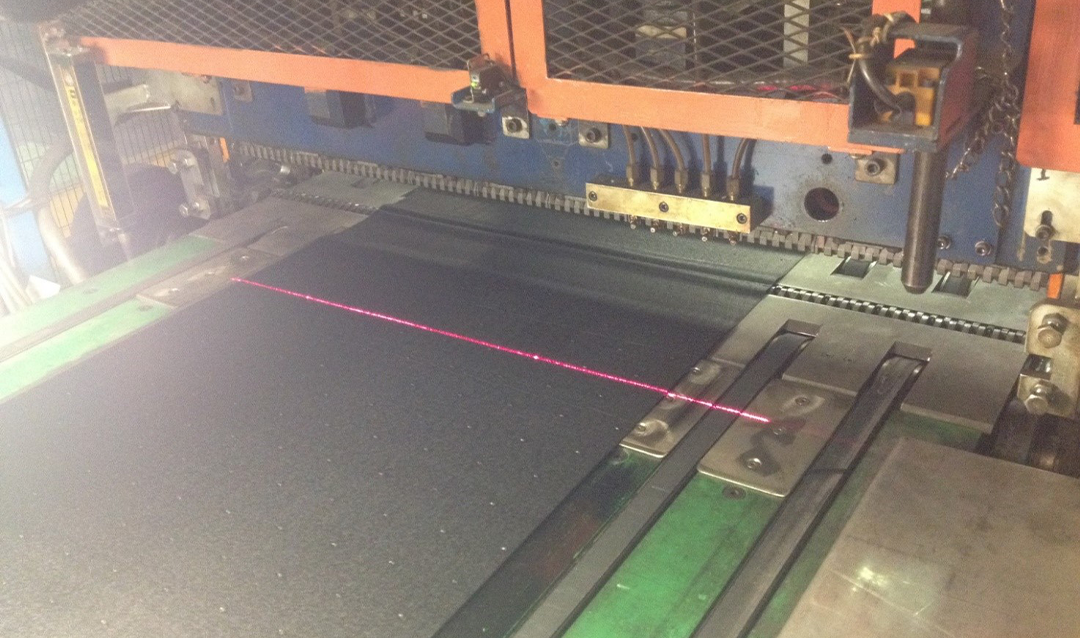

Tread Band Length Measurement Application

This application ensures precise in-line measurement of tread bands cut to match the circumference of the green tire being produced. By measuring with millimeter-level accuracy, the system detects the inclined cut angle and incorporates it into the length calculation, guaranteeing a seamless joint without overlap. Easily integrable into existing production lines, it provides reliable quality control for consistent and accurate tread band preparation.

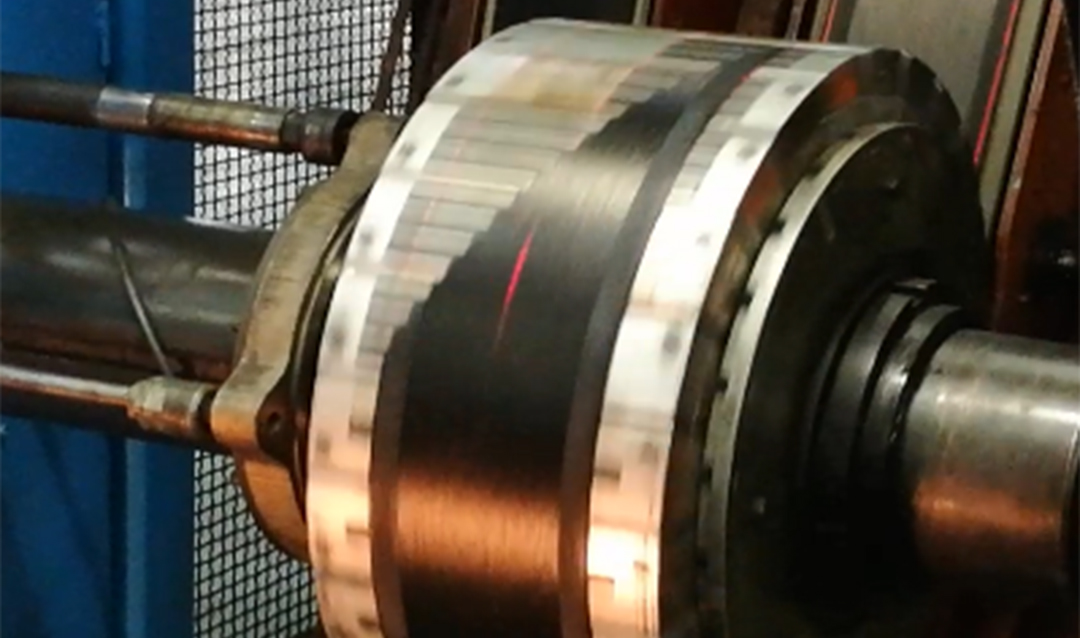

Automated Belt Quality Control

An advanced inspection system that leverages high-resolution 3D cameras and laser technology to deliver precise, real-time quality control of tire belts. By meticulously analyzing the belt’s surface for defects such as wrinkles, folds, holes and dimensional inconsistencies, we ensure optimal performance and durability.

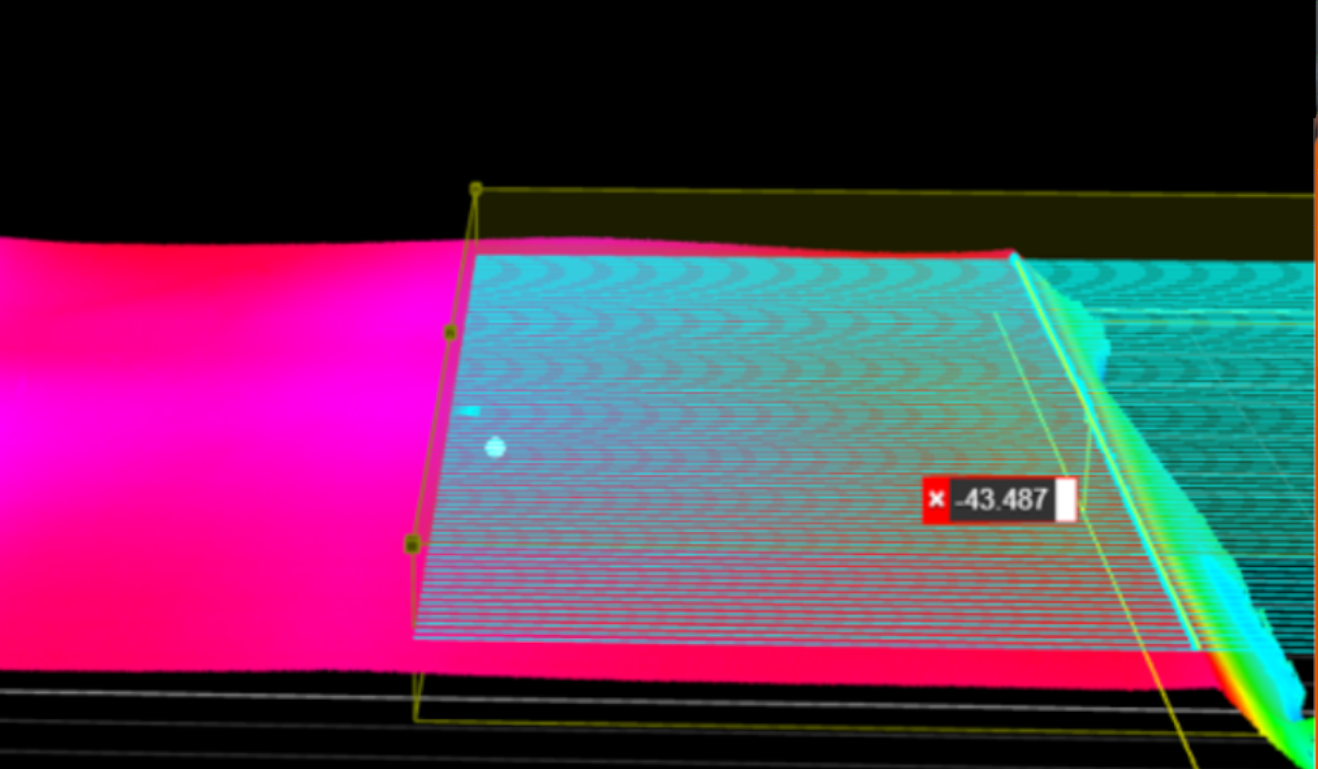

Automated Belt Coupling Quality Control

An advanced automated system that utilizes high-resolution 3D cameras and laser technology to create a custom profilometer capable of inspecting the entire width of the belt. By analyzing the junctions along the edges and center of the belt, we ensure accurate and efficient quality control, preventing common defects such as dog ears or folds.

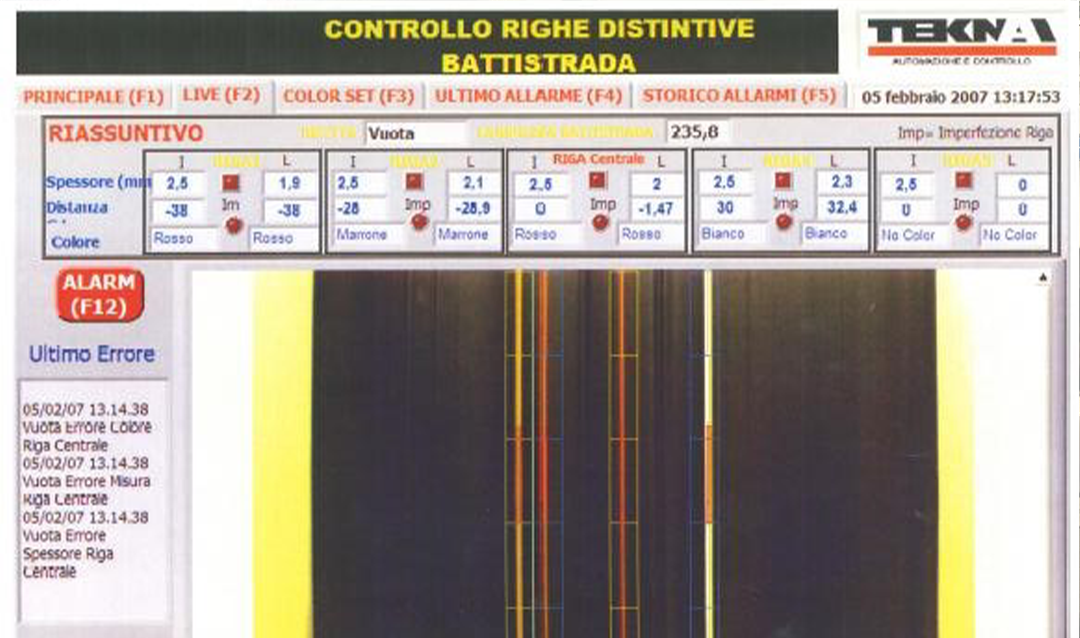

Automated Color Band Verification on Tire Tread Production Lines

An advanced automated system utilizes RGB color cameras to ensure accurate verification of color bands on tire tread production lines. The software meticulously checks the correspondence of colors and their positioning relative to the edges of the tread, ensuring strict adherence to recipe specifications.

In-Line Bead Assembly Quality Control

An automated system that ensures the correct junction and distribution of rubber on the bead core during the beading process. Using advanced 3D vision technology, the rubber thickness and junction quality is accurately measure, guaranteeing optimal pneumatic bead assembly.

Automated Belt Presence and Positioning Verification

An advanced automated system that utilizes profilometers to accurately measure the thickness and positioning of belts during the pneumatic assembly process. This ensures not only that belts are present but also that they are correctly positioned, preventing assembly errors and enhancing overall tire quality.

First Cured Tire OCR and Symbol Validation

Taking into account the plant sheet specification of the tire in test, consisting of a list of all the writings and symbols that have to be imprinted on the tire, verifies if all the elements on the list are correctly imprinted and placed on the tire surface. Additional controls can be operated, as the analysis of the deterioration of the mold, where the stamp height of the characters on the tire in test is compared to the expected one. A limit tolerance can be set to raise an alert when the mold is getting dirty, deteriorated or damaged.

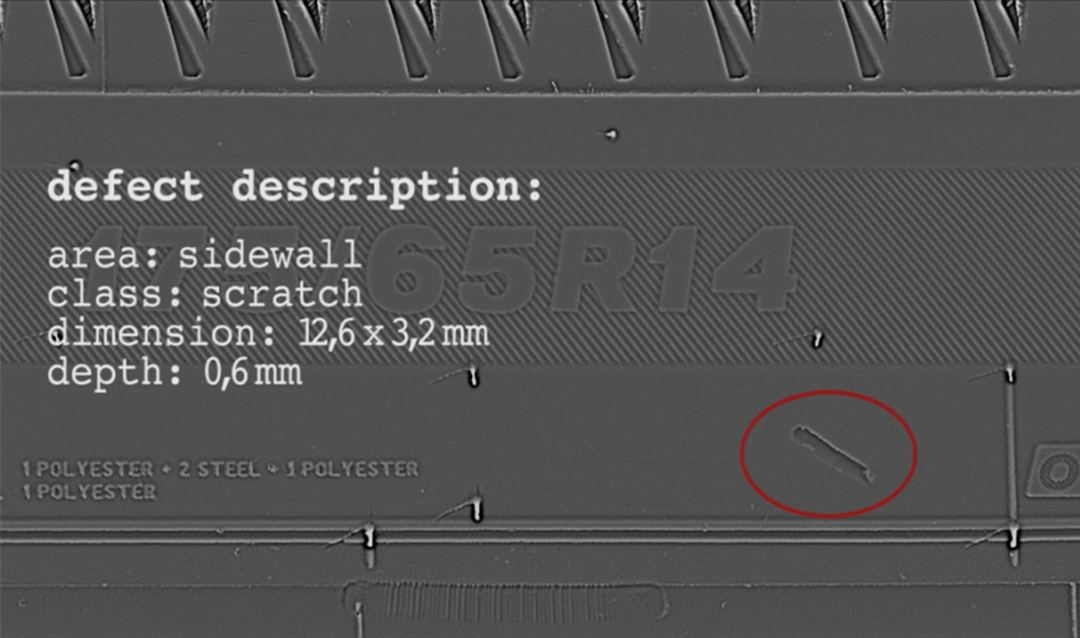

Finished Tire Defect Analysis

A comprehensive solution for automatic tire quality control using laser profilometry to accurately detect, classify, and measure all visible defects on both the inner and outer surfaces of the tire, including cuts, blisters, and embedded foreign objects. With AI-powered accuracy, our system ensures that only the highest quality tires reach the market.

Barcode and IPC Code reading system for car tyres

Barcode and IPC Code reading system for car tires installed on belts/roller conveyors to verify the correct typology, quality, loading sequence of tires in the warehouse or on trucks in accordance with the loading list. Interfacing the system to the MES for the acquisition of the loading list and data management.

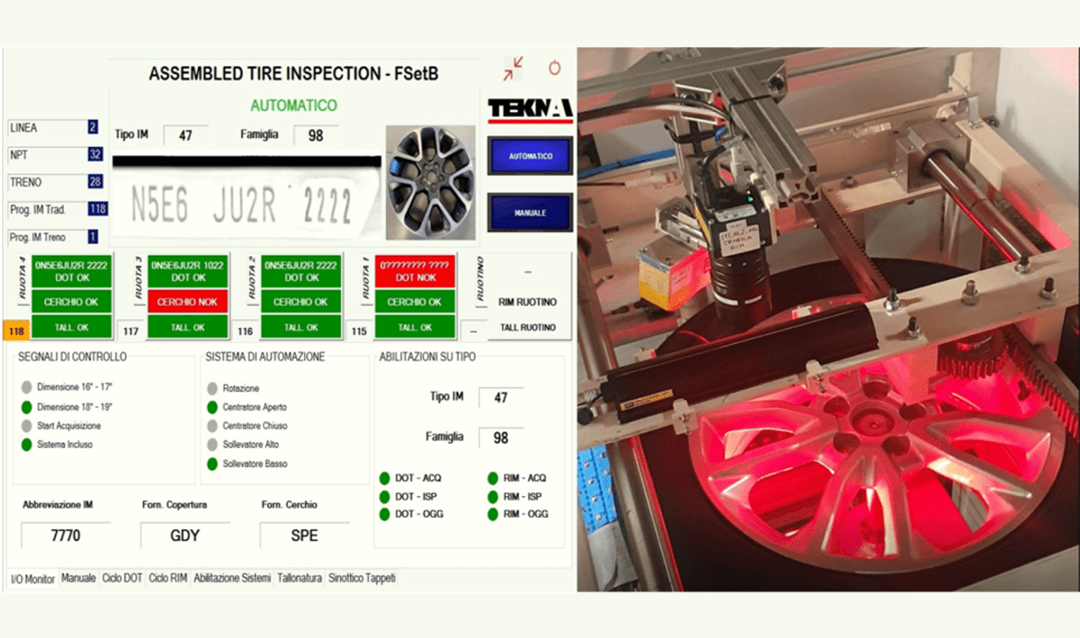

Comprehensive Tire Dot Code and Rim Inspection

An advanced automatic system that combines laser profilometry and Color cameras for comprehensive tire and wheel inspection. By scanning the tire and using OCR to read the DOT code on the 3D data, we accurately identify the tire. Simultaneously, we capture the wheel image and employ image classification algorithms to determine its shape, model, and intended color. This ensures that the correct tire is paired with the appropriate wheel, preventing assembly errors and enhancing overall vehicle safety.

Let’s Build Something Together

“As your innovation partner, we design cutting-edge technology solutions tailored to your needs, optimizing your production process and driving your company towards the future.”

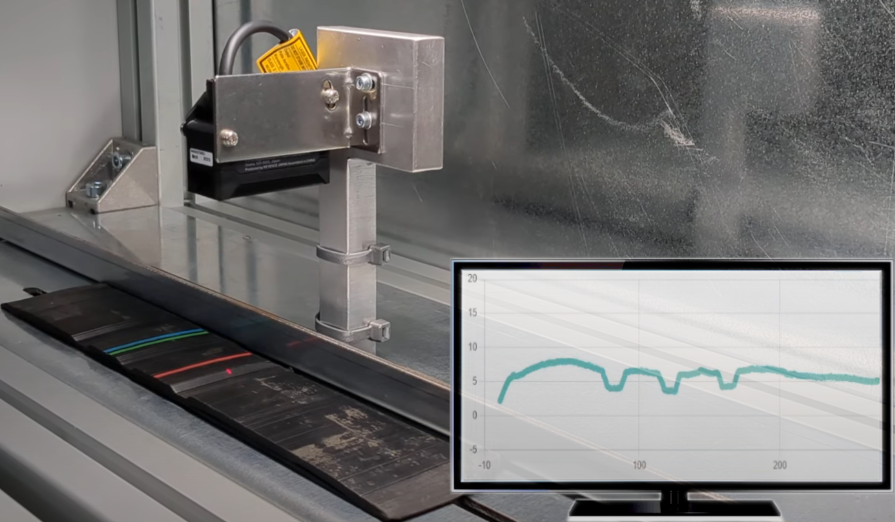

LASER PROFILOMETRY

Laser profilometry offers incredibly fast, non-contact 3D surface measurements with exceptional resolution. By using triangulation between a laser line and an area scan camera, this technique enables a detailed three-dimensional reconstruction of tire surfaces in a remarkably short cycle time, making it ideal for quality control and process monitoring.

Color line scan cameras

Color line scan cameras offer high-speed, non-contact image acquisition with exceptional color resolution. These cameras capture detailed, full-color line images at incredibly fast frame rates, making them ideal for applications that require precise color inspection and measurement. By employing advanced image processing techniques, color line scan cameras provide detailed color data for tasks such as colorimetric analysis, defect detection, and object recognition.

Area scan cameras

Area scan cameras, offer versatile image acquisition with high resolution and a wide field of view. These cameras capture full-color images in a single exposure, making them ideal for applications requiring detailed scene analysis and object recognition. Equipped with advanced image processing capabilities, matrix cameras provide rich visual data for tasks such as machine vision, quality inspection, and surveillance.

Projected pattern sensors

Projected pattern sensors offer precise, non-contact 3D measurements and surface inspection. By projecting a structured light pattern onto a target object and analyzing the distorted pattern captured by a camera, these sensors create detailed 3D point clouds or surface maps.

For smaller fields of view, projected pattern sensors excel at surface inspection, allowing for meticulous examination of intricate details. In applications requiring larger fields of view, such as bin picking, these sensors can accurately locate and orient objects within a cluttered environment.